How Vertical Traction Machines Enhance Elevator Efficiency

Vertical traction machines are a cornerstone of modern elevator systems, playing a critical role in improving efficiency and performance. Unlike traditional hydraulic elevators, these systems utilize a series of pulleys and cables to move the elevator car, which leads to numerous benefits that enhance the overall functionality of vertical transportation in buildings. In this section, we will explore the mechanisms of vertical traction machines and how they contribute to elevator efficiency.

Superior Energy Efficiency

One of the most significant advantages of vertical traction machines is their energy efficiency. By employing a pulley system, these machines can significantly reduce the amount of energy required to lift heavy loads compared to hydraulic systems. Key factors contributing to energy efficiency include:

- Counterweight Mechanism: Vertical traction machines incorporate a counterweight that balances the weight of the elevator car, thereby reducing the energy needed for lifting and lowering the car.

- Regenerative Drives: Many modern vertical traction machines are equipped with regenerative drives, which capture energy that would otherwise be wasted during braking and return it to the power grid.

- Variable Speed Control: These machines can adjust their speed based on demand, allowing for efficient operation during peak and off-peak hours.

Space-Saving Design

Vertical traction machines are designed to be compact and efficient, which translates into space-saving advantages within a building. Here’s how they contribute to a more effective design:

- Smaller Machine Room: The compact nature of vertical traction systems allows for smaller machine rooms, freeing up valuable real estate within buildings.

- Reduced Shaft Size: The design of these elevators permits a smaller shaft size, optimizing the building’s structural footprint.

- Flexibility in Installation: The versatility in where and how these systems can be installed enables better architectural designs without compromising efficiency.

Improved Ride Quality

Another area where vertical traction machines shine is in providing a smoother ride experience. The precision of the lifting mechanism contributes to ride quality in several ways:

- Minimal Jerking: The gradual acceleration and deceleration of the elevator car reduce the jerking that is often felt in hydraulic systems.

- Better Load Handling: Vertical traction machines adapt well to varying loads, ensuring a consistent ride regardless of how many passengers are in the elevator.

- Quiet Operation: This type of machinery often operates more quietly than hydraulic systems, adding to passenger comfort.

Enhanced Speed and Performance

In terms of speed and performance, vertical traction machines offer significant improvements over their hydraulic counterparts. This is particularly evident in high-rise buildings where swift transport is crucial:

- Faster Travel Times: Vertical traction elevators can travel at higher speeds, accommodating the needs of skyscraper living and working.

- Increased Efficiency: By utilizing sophisticated control systems, vertical traction machines manage elevator wait times effectively, reducing congestion during peak hours.

- Advanced Technology Integration: Many of these systems can be integrated with smart building technologies for improved operational efficiency and user experience.

In conclusion, vertical traction machines significantly enhance elevator efficiency through their superior energy use, compact design, improved ride quality, and performance. These advanced systems not only contribute to the sustainability of modern buildings but also align with the growing demand for efficient vertical transportation solutions in urban environments.

What Makes Vertical Traction Machines Ideal for Modern Buildings

In the realm of vertical transportation, vertical traction machines have emerged as a preferred choice for modern buildings. From enhancing energy efficiency to offering superior ride quality, these machines are optimized for the demands of contemporary architectural design. Below, we will explore the key features and benefits that contribute to their suitability in modern construction projects.

Energy Efficiency and Sustainability

One of the primary advantages of vertical traction machines is their energy efficiency. These machines utilize a counterweight system, which reduces the amount of energy required to lift the elevator cab. This leads to several benefits:

- Lower Energy Consumption: The counterweight significantly minimizes the energy needed, making vertical traction machines an eco-friendly choice.

- Regenerative Drives: Many modern machines are equipped with regenerative drives that capture energy during descents and feed it back into the building's power system.

- Reduced Carbon Footprint: By utilizing less energy, vertical traction machines contribute to lower greenhouse gas emissions, aligning with global sustainability goals.

Space Efficiency and Versatility

Vertical traction machines are compact and versatile, making them ideal for various building designs. Their design allows for:

- Smaller Machine Rooms: These machines can often be installed in smaller machine rooms, freeing up valuable space within the building.

- Flexible Installation Options: They can be installed in various configurations, catering to different architectural layouts and maximizing usable space.

- Seamless Integration: The design and technology of vertical traction machines enable them to integrate smoothly into both new and retrofitted buildings.

Improved Ride Quality and Performance

In terms of ride comfort and performance, vertical traction machines surpass many traditional systems. Key factors include:

- Smooth Operation: The use of steel cables ensures a smoother and quieter ride, minimizing noise and vibrations for passengers.

- Acceleration Control: Vertical traction machines provide superior acceleration and braking capabilities, enhancing overall ride comfort.

- Lower Maintenance Needs: These machines tend to require less maintenance, reducing downtime and ensuring reliable performance for users.

Advanced Technology and Safety Features

Modern vertical traction machines are equipped with cutting-edge technology and safety features, which include:

- Smart Monitoring Systems: Advanced monitoring and diagnostic tools help in predicting maintenance needs and improving operational efficiency.

- Enhanced Safety Protocols: Features such as door sensors and emergency braking systems ensure passenger safety in various scenarios.

- Integration with Smart Building Systems: These machines can be seamlessly connected to a building's overall management system for efficient operation.

In summary, vertical traction machines are ideal for modern buildings due to their energy efficiency, space-saving design, enhanced ride quality, and integration of advanced technology. Their ability to meet the ever-evolving demands of urban architecture, while focusing on sustainability and occupant comfort, makes them an indispensable solution in today's construction landscape. As industries continue to prioritize energy conservation and innovation, the adoption of vertical traction machines is set to rise, further solidifying their status as a cornerstone of modern vertical transportation.

Benefits of Using Vertical Traction Machines in High-Rise Construction

Vertical traction machines are essential components in modern high-rise buildings, providing efficient and reliable vertical transportation for occupants and goods. As cities grow taller, the demand for advanced elevator technologies increases. Here, we explore the numerous benefits that vertical traction machines offer for high-rise construction projects.

Energy Efficiency

One of the primary advantages of vertical traction machines is their energy efficiency. Unlike hydraulic systems, which can consume significant energy, vertical traction machines utilize a counterweight system that reduces the amount of energy required to lift the elevator car. This can result in:

- Lower operational costs due to reduced energy consumption

- Decreased carbon footprint, aligning with sustainability goals

- Longer lifespan of the elevator system, making it more cost-effective in the long run

Space Savvy Design

High-rise buildings often have limited space for infrastructure. Vertical traction machines require less space than traditional hydraulic systems, making them more suitable for tall structures. This compact design means:

- More usable floor space in buildings, enhancing architectural design flexibility

- Efficient installation within smaller shafts, optimizing the building layout

- Reduced construction costs, as less material is needed for elevator pits and machine rooms

Superior Performance

Vertical traction machines are known for their smooth, reliable performance. High-rise buildings demand elevators that can handle heavy traffic and operate quickly. With vertical traction machines, you get:

- Rapid acceleration and deceleration, ensuring minimal wait times for passengers

- Enhanced ride quality with less vibration and noise

- A greater range of travel, accommodating elevators that can ascend hundreds of feet without compromising performance

Greater Load Capacity

In high-rise buildings, vertical traction machines can handle substantial load capacities, making them ideal for various applications. Their strengths include:

- Transporting more passengers or heavy goods in a single trip, which is vital for commercial buildings

- Custom configurations that allow for specialized uses, such as freight elevators

- Robust safety mechanisms that protect both passengers and freight, ensuring reliable operation under various conditions

Advanced Technology Integration

As technology evolves, vertical traction machines can be equipped with advanced features that enhance their functionality. These integrations include:

- Smart controls that optimize elevator dispatching based on real-time traffic patterns

- Sustainability features like regenerative drives, which capture and reuse energy

- Remote monitoring capabilities that allow for predictive maintenance, reducing downtime

In summary, vertical traction machines offer a multitude of benefits for high-rise construction projects, ranging from energy efficiency and space-saving designs to superior performance and integration of advanced technologies. Their ability to meet the demands of modern building environments makes them a popular choice among architects, engineers, and developers alike. As urban landscapes continue to evolve, vertical traction machines will play a crucial role in elevating the standards of vertical transportation in high-rise buildings.

Understanding the Mechanisms Behind Vertical Traction Machines

Vertical traction machines have revolutionized the way elevators operate, providing efficient, reliable, and smooth vertical transport in modern buildings. Their design and mechanics are integral to their operation, influencing everything from energy consumption to maintenance needs. This section delves into the key mechanisms that set vertical traction machines apart from other elevator systems.

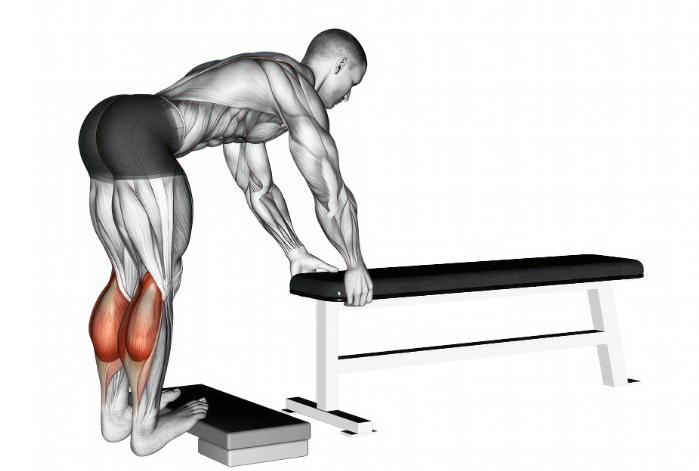

Core Components of Vertical Traction Machines

The mechanics of vertical traction machines include several core components that work in harmony to create a safe and effective means of vertical transportation. These components include:

- Motor: The heart of the system, typically an electric motor that drives the hoisting operation.

- Sheave: A grooved wheel around which the cable or rope passes, facilitating the movement of the elevator car.

- Rope or Cable: High-strength steel cables or synthetic ropes that connect the elevator car to the counterweight and are crucial for load balancing.

- Counterweight: A weight that offsets the weight of the elevator car, reducing the energy required by the motor.

- Control System: Sophisticated electronics that manage the operation of the elevator, ensuring smooth stops and starts, as well as safety features.

The Operating Principle of Vertical Traction Machines

At its core, the functionality of vertical traction machines is based on the principles of physics and mechanics. The operational process can be summarized as follows:

- The electric motor receives a signal from the control system, initiating its operation.

- As the motor turns, it causes the sheave to rotate, which pulls the attached cable or rope.

- The movement of the cable lifts the elevator car upward while simultaneously allowing the counterweight to descend.

- This counterbalance greatly reduces the load on the motor, improving energy efficiency.

- The entire process is monitored by safety mechanisms that prevent overloading and ensure a smooth ride.

Advantages of Vertical Traction Machines

The mechanisms behind vertical traction machines provide several advantages that make them preferred in various applications:

- Energy Efficiency: The counterweight system minimizes energy consumption, making it an eco-friendly choice.

- Space-Saving Design: Vertical traction machines require less space than traditional hydraulic systems, benefiting building architecture.

- Smooth Operation: The mechanics allow for a smoother start and stop, enhancing passenger comfort.

- High Speed: They can achieve higher speeds, making them ideal for high-rise buildings.

- Reduced Maintenance: Their mechanical design can lead to lower maintenance requirements compared to hydraulic systems.

In summary, vertical traction machines employ a sophisticated blend of components and mechanisms that contribute to their efficiency and effectiveness. Understanding these mechanisms not only highlights the engineering marvel that these machines represent but also emphasizes their critical role in modern architecture and infrastructure.